王云江 研究员、博士生导师

中国科学院力学研究所 超常环境非线性力学全国重点实验室

中国科学院大学工程科学学院 岗位教授

电子邮件:yjwang@imech.ac.cn

电 话:010-82543408

通信地址:北京市海淀区北四环西路15号

邮政编码:100190

概况

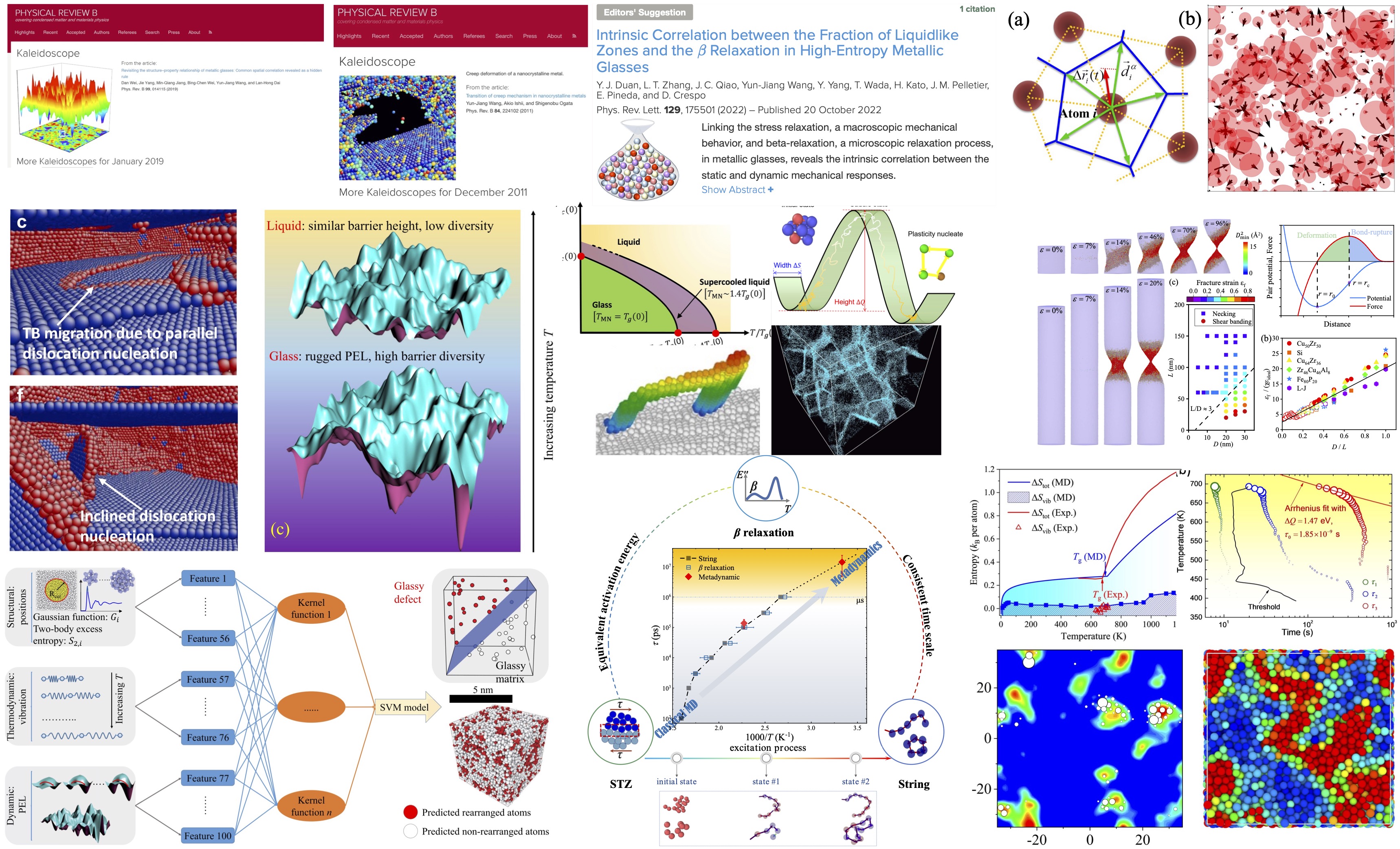

王云江,中科院力学所研究员、博士生导师,国科大岗位教授。2005年于河北师范大学获学士学位,2010年于清华大学获博士学位。2010至2013年,先后任大阪大学博士后研究员、京都大学助理教授。2014年开始在非线性力学国家重点实验室工作,从事材料物理与固体力学交叉的多尺度模拟研究,兴趣包括非晶态物理与力学、纳米力学、跨尺度算法与应用、材料基因工程与机器学习等。发表论文百余篇,包括物理类Phys. Rev. Lett. (3), Phys. Rev. B/E/Mater./Res. (21), APL (3), Sci. Adv.;力学类JMPS (2), IJP (10);材料类Acta Mater. (13), Scr. Mater. (6), npj Comput. Mater., Nano Lett. 等, Google Scholar引用3400余次,h-index = 34。主持或参与自然科学基金、国家重点研发计划、中科院战略性先导等项目。2010年获日本学术振兴会 (JSPS) 奖学金,2017年入选中国科学院青年创新促进会会员、2021获评优秀会员。担任《计算力学学报》、《Materials Research Letters》、《Journal of Applied Physics》等期刊编委或客座编辑。

简历

- 2018/11 – 至今 中国科学院力学研究所,研究员、博士生导师

- 2014/01 – 2018/10 中国科学院力学研究所,副研究员

- 2013/01 – 2013/12 京都大学,特定助理教授

- 2010/10 – 2012/12 大阪大学,JSPS外国人特别研究员

- 2005/09 – 2010/07 清华大学,博士

- 2001/09 – 2005/07 河北师范大学,学士

研究领域

- 计算材料学 – 分子动力学、跨时间尺度算法与应用、增强采样与自由能计算;第一性原理与电子结构;蒙特卡洛、动力学蒙特卡洛;材料基因工程与机器学习等。

- 物理力学 – 跨尺度力学;固体变形物理与力学;新金属材料力学与强韧化;材料构效关系;弹塑性本构等。

- 材料物理 – 玻璃物理与玻璃转变,复杂物质动力学;固体缺陷,弹塑性变形,位错形核与运动、扩散;材料热力学与动力学,晶格动力学;热激活理论;蠕变、应力松弛,内耗,相变等。

研究团队:GDP (Group of Deformation Physics)

- 博士生:陶佳乐、曹琳莉

- 硕士生:熊浩智、黄隆州、雷挺

左起:熊浩智 戴仕诚 赵坤 杨增宇 陶佳乐 王云江 曹琳莉 王晓实

桃李芬芳

- 2017 – 田智立 博士 航天三院

- 2018 – 杨 杰 硕士 中国工商银行

- 2019 – 魏 丹 博士 大阪大学

- 2019 – 韩 懂 硕士 田纳西大学研究生

- 2019 – 杨奕博 本科 (国科大) 芝加哥大学研究生

- 2021 – 梁伦伟 博士 三一重工

- 2021 – 王一舟 硕士 比亚迪

- 2022 – 彭正瀚 本科 (四川大学) 斯坦福大学研究生

- 2022 – 吕国建 博士后 西北工业大学

- 2023 – 王晓实 博士 比亚迪

- 2023 – 杨增宇 博士 工程物理研究院

- 2023 – 刘淑兰 访问学者 唐山学院

- 2024 - 戴仕诚 博士 工程物理研究院

- 2024 - 赵坤 博士 陕西水利厅

招生招聘信息

招收具有力学/物理/材料背景的研究生,1-2名/年;

- 欢迎国内外优秀博士生联系博士后、特别研究助理合作研究事宜。

招生专业

- 固体力学

奖励

2023 – Acta Materialia, Scripta Materialia Outstanding Reviewer Award

2023 – IOP (Model. Simul. Mater. Sci. Eng.) Outstanding Reviewer Award

2021 – 中国科学院青年创新促进会优秀会员

2017 – 中国科学院青年创新促进会会员

2010 – 日本学术振兴会(JSPS)研究员奖学金

发表论文

Linked to Google Scholar; Researchgate; WoS; Orcid

H. Kang, H. R. Liu, Q. A. Li, N. N. Ren, Y. J. Wang, and P. F. Guan

Invariant topological feature of atomic packing in a model metallic glass

Acta Mater. 289, 120925 (2025).

L. Xu, X. Z. Tang, Y. F. Guo, and Y. J. Wang

Decoupling the chemical-ordering-dependent dislocation and diffusion contributions to creep in multi-principal element alloy

Mater. Res. Lett. 13, 122 (2025).

L. L. Cao, K. Zhao, and Y. J. Wang

Phonon dynamics in 3D quasicrystals versus amorphous solids

J. Appl. Phys. 137, 055104 (2025).

S. Y. Meng, Q. Hao, B. Wang, Y. J. Wang, Eloi Pineda and J. C. Qiao

Quantitative assessment of physical aging on dynamical heterogeneity of amorphous alloys: Insight from stress relaxation

J. Appl. Phys. 137, 055108, (2025).

Q. Hao, D. S. Yang, E. Pineda, C. Fusco, L. Chazeau, Y. J. Wang, Y. Yang, V. A. Khonik, J. C. Qiao

Reproducing the thermal effects induced by aging in La-based amorphous alloy

J. Appl. Phys. 137, 085104 (2025).

Q. Hao, G. H. Xing, E. Pineda, C. Fusco, L. Chazeau, J. Pelletier, Y. J. Wang, Y. Yang, and J. C. Qiao

Deciphering the α relaxation and the anelastic-to-plastic transition in the deep glassy state

Sci. China Phys. Mech. Astron. 68, 234611 (2025).

G. H. Xing, Q. Hao, G. J. Lyu, F. Zhu, Y. J. Wang, Y. Yang, E. Pineda, and J.C. Qiao

Integrating dynamic relaxation with inelastic deformation in metallic glasses: Theoretical insights and experimental validation

J. Mater. Sci. Technol., 218, 135-152 (2025).

Y. J. Bai, C. Yang, Z. S. Liu, Q. Y. Jiang, Y. J. Wang, K. Zhang, Y. Z. Liu, Y. D. Li, and B. C. Wei

Mechanical anisotropy in additively manufactured laminated high-entropy alloys: The role of interface geometry

J. Mater. Sci. Technol. 210, 72 (2025).

Y. J. Duan, M. Nabahat, Y. Tong, L. Ortiz-Membrado, E. Jiménez-Piqué, K. Zhao, Y. J. Wang, Y. Yang, T. Wada, H. Kato, J. M. Pelletier, J. C. Qiao, and E. Pineda

Connection between Mechanical Relaxation and Equilibration Kinetics in a High-Entropy Metallic Glass

Phys. Rev. Lett. 132, 056101 (2024).

Z. Y. Yang, Q. Miao, J. K. Dan, M. T. Liu, Y. J. Wang

Structural mechanism of glass transition uncovered by unsupervised machine learning

Acta Mater. 281, 120410 (2024).

S. C. Dai, Y. Yang, and Y. J. Wang

Role of chemical disorder in slowing down diffusion in complex concentrated alloys

Phys. Rev. Mater. 8, 033607 (2024).

L. L. Cao and Y. J. Wang

Dynamics–Entropy Relationship in Metallic Glasses

J. Phys. Chem. Lett. 15, 811 (2024).

J. L. Tao, and Y. J. Wang

An Artificial Intelligence Constitutive Model for Amorphous Solids Utilizing Graph Neural Networks

JOM 76, 5777 (2024).

S. Y. Liang, F. Zhu, Y. J. Wang, E. Pineda, T. Wada, H. Kato, J. C. Qiao

On the kinetics of structural evolution in metallic glasses

Int. J. of Eng. Sci. 205, 104146 (2024).

S. Y. Liang, L. T. Zhang, Y. J. Wang, B. Wang, J. M. Pelletier and J. C. Qiao

A model on the coupling between cyclic fatigue and microstructure evolution in a metallic glass

Int. J. of Fatigue 187, 108446 (2024).

L. T. Zhang, Y. J. Wang, Y. Yang, T. Wada, H. Kato, J. C. Qiao

Mechanical memory and relaxation decoupling of metallic glasses in homogenous flow

Int. J. Mech. Sci. 281, 109661 (2024).

Y. J. Bai, C. Yang, Z. S. Liu, Q. Y. Jiang, Y. J. Wang, K. Zhang, Y. Z. Liu, Y. D. Li, and B. C. Wei

Mechanical anisotropy in additively manufactured laminated high-entropy alloys: The role of interface geometry

J. Mater. Sci. Technol. 210, 72 (2024).

Q. Hao, G. J. Lyu, E. Pineda, J. M. Pelletier, Y. J. Wang, Y. Yang, J. C. Qiao

Deciphering non-elastic deformation in amorphous alloy: Simultaneous aging-induced ordering and rejuvenation-induced disordering

Int. J. Plast. 175, 103926 (2024).

L. T. Zhang, Y. J. Wang, M. Nabahat, E. Pineda, Y. Yang, J. M. Pelletier, D. Crespo, J. C. Qiao

Creep Deformation in Metallic Glasses: A Global Approach with Strain as an Indicator within Transition State Theory

Int. J. Plast. 174, 103923 (2024).

F. Zhu, G. H. Xing, Y. J. Wang, E. Pineda, and J.C. Qiao

Quantifying contribution of hierarchically correlated shear microdomains underlying creep in metallic glass

Int. J. Plast. 174, 103900 (2024).

X. Gao, S. C. Dai, Y. Teng, Q. Wang, Z. B. Zhang, Z. Y. Yang, M. Park, H. Wang, Z. Jia, Y. J. Wang, and Y. Yang

Ultra-Efficient and Cost-Effective Platinum Nanomembrane Electrocatalyst for Sustainable Hydrogen Production

Nano-Micro Lett. 16, 108 (2024).

F. Zhu, G.H. Xing, Y. J. Wang, E. Pineda, and J.C. Qiao

Quantifying contribution of hierarchically correlated shear microdomains underlying creep in metallic glass

Sci. China Phys. Mech. Astron. 67, 256111 (2024).

H. L. Zhuang, Z. Z. Yu, L. Li, Y. J. Wang, and L, K. Béland

Multi-principal element materials: Structure, property, and processing

J. Appl. Phys. 135, 010401 (2024).

P. Y. Cao, J. Wang, P. Jiang, Y. J. Wang, F. P. Yuan, and X. L. Wu

Prediction of chemical short-range order in high-/medium-entropy alloys

J. Mater. Sci. Technol. 169, 115 (2024).

S. Y. Liang, L. T. Zhang, B. Wang, Y. J. Wang, E. Pineda, and J. C. Qiao,

Structural rejuvenation and relaxation of a metallic glass under the periodically thermal-mechanical loading

Intermetallics 164, 108115 (2024).

– 2023 –

X. S. Wang and Y. J. Wang

Phonon instability of a multi-principal element alloy

Phys. Rev. B 107, 184116 (2023).

P. A. Santos-Florez, S. C. Dai, Y. Yao, H. Yanxon, L. Li, Y. J. Wang, Qiang Zhu, and X. X. Yu

Short-range order and its impacts on the BCC MoNbTaW multi-principal element alloy by the machine-learning potential

Acta Mater. 255, 119041 (2023).

J. L. Tao, Z. Y. Yang, and Y. J. Wang

Structural rationale for boson peak in metallic glass informed by an interpretable neural network model

Phys. Rev. Res. 5, 023113 (2023).

K. Zhao, Y. J. Wang, and P. H. Cao

Fracture universality in amorphous nanowires

J. Mech. Phys. Solids 173, 105210 (2023).

X. S. Wang and Y. J. Wang

Disorder-order transition in multiprincipal element alloy: A free energy perspective

Phys. Rev. Mater. 7, 033606 (2023).

Z. Y. Zhou, Y. Sun, L. Gao, Y. J. Wang, H. B.Yu

Fundamental links between shear transformation, β relaxation, and string-like motion in metallic glasses

Acta Mater. 246, 118701 (2023).

L. Qian, W. Q. Yang, J. S. Luo, Y. J. Wang, K. C. Chan, and X. S. Yang

Amorphous Thickness-Dependent Strengthening–Softening Transition in Crystalline–Amorphous Nanocomposites

Nano Lett. 23, 11288 (2023).

Y. J. Bai, Y. D. Li, Y. J. Wang, K. Zhang, Q. Y. Jiang, Z. S. Liu, Z. Hu, and B. C. Wei

Wavy interface enables extra strengthening in an additively manufactured high-entropy alloy with Mortise-Tenon architecture

Int. J. Plast. 170, 103777 (2023).

Q. Hao, E. Pineda, Y. J. Wang, Y. Yang and J. C. Qiao

Reversible anelastic deformation mediated by β relaxation and resulting two-step deformation in a La60Ni15Al25 metallic glass

Phys. Rev. B 108, 024101 (2023).

F. Zhu, G.H. Xing, G.J. Lyu, L.T. Zhang, Y. J. Wang, Y. Yang, J.M. Pelletier, J.C. Qiao

Physics-motivated fractional viscoelasticity model for dynamic relaxation in amorphous solids

Int. J. Plast. 164, 103588 (2023).

L. T. Zhang, Y. J. Wang, Y. Yang, J. C. Qiao

Training β relaxation to rejuvenate metallic glasses

J. Mater. Sci. Technol. 158, 53 (2023).

Y. J. Bai, G. J. Lyu, Y. J. Wang, T. Y. Chen, K. Zhang, and B. C. Wei

Laser shock peening strengthens additively manufactured high-entropy alloy through novel surface grain rotation

Mater. Sci. Eng. A 871, 144886 (2023).

L. Y. Li, G. J. Lyu, H. Z. Li, C. T. Fan, W. X. Wen, H. J. Lin, B. Huang, S. Sohrabi, S. Ren, X. Liang, Y. J. Wang, J. Ma, and W. H. Wang

Ultra-fast amorphization of crystalline alloys by ultrasonic vibrations

J. Mater. Sci. Technol. 142, 76 (2023).

L. W. Liang, S. C. Dai, Y. Chen, H. Y. Wang, Y. J. Wang and L. H. Dai

Emergent failure transition of pearlitic steel at extremely high strain rates

Comput. Mater. Sci. 219, 112005 (2023).

J. Duan, Y. J. Wang, L. H. Dai, and M. Q. Jiang

Elastic interactions of plastic events in strained amorphous solids before yield

Phys. Rev. Materials 7, 013601 (2023).

S. Shuang, G. J. Lyu, D. Chung, X. Z. Wang, X. Gao, H. H. Mao, W. P. Li, Q. F. He, B. S. Guo, X. Y. Zhong, Y. J. Wang, and Y. Yang

Unusually high corrosion resistance in MoxCrNiCo medium entropy alloy enhanced by acidity in aqueous solution

J. Mater. Sci. Technol. 139, 59 (2023).

L. T. Zhang, Y. J. Duan, Y. J. Wang, Y. Yang, and J. C. Qiao

Tailoring mechanical properties of bulk metallic glasses via modulating cooling from supercooled liquid

Sci. China Technol. Sci. 66, 173 (2023).

– 2022 –

Y. J. Duan, L. T. Zhang, J. C. Qiao, Y. J. Wang, Y. Yang, T. Wada, H. Kato, J. M. Pelletier, E. Pineda, and D. Crespo

Intrinsic Correlation between the Fraction of Liquidlike Zones and the β Relaxation in High-Entropy Metallic Glasses

Phys. Rev. Lett. 129, 175501 (2022). (Editors' Suggestion)

Y. J. Bai, K. Zhang, T. Y. Chen, Z. S. Liu, Y. J. Wang, B. C. Wei

Alterable tension-compression asymmetry in work hardening of an additively manufactured dual-phase high-entropy alloy

Int. J. Plast. 158, 103432 (2022).

L. T. Zhang, Y. J. Wang, Y. Yang, and J. C. Qiao

Aging and rejuvenation during high-temperature deformation in a metallic glass

Sci. China-Phys. Mech. Astron. 65, 106111 (2022).

Y. L. Guan, Y. J. Wang, and W. D. Song

Modulating mechanical performances of metallic amorphous materials through phase gradient

Int. J. Mech. Sci. 234, 107680 (2022).

L. T. Zhang, Y. J. Wang, E. Pineda, Y. Yang, and J. C. Qiao

Achieving structural rejuvenation in metallic glass by modulating β relaxation intensity via easy-to-operate mechanical cycling

Int. J. Plast. 157, 103402 (2022).

Z. Y. Yang, Y. J. Wang, and L. H. Dai

Hidden spatiotemporal sequence in transition to shear band in amorphous solids

Phys. Rev. Research 4, 023220 (2022).

X. J. Wang, Y. Z. Lu, X. Lu, J. T. Huo, Y. J. Wang, W. H. Wang, L. H. Dai, and M. Q. Jiang

Elastic criterion for shear-banding instability in amorphous solids

Phys. Rev. E 105, 045003 (2022).

Z. Y. Yang and Y. J. Wang

Ergodic structural diversity predicts dynamics in amorphous materials

Front. Mater. (2022).

L. T. Zhang, Y. J. Wang, E. Pineda, H. Kato, Y. Yang, and J. C.Qiao

Sluggish dynamics of homogeneous flow in high-entropy metallic glasses

Scr. Mater. 214, 114673 (2022).

Q. Hao, G. J. Lyu, E. Pineda, J. M. Pelletier, Y. J. Wang, Y. Yang, and J. C. Qiao

A hierarchically correlated flow defect model for metallic glass: Universal understanding of stress relaxation and creep

Int. J. Plast. 154, 103288 (2022).

Z. Y. Yang, Y. J. Wang, and A. Zaccone

Correlation between vibrational anomalies and emergent anharmonicity of the local potential energy landscape in metallic glasses

Phys. Rev. B 105, 014204 (2022).

Y. Z. Wang and Y. J. Wang

Disentangling diffusion heterogeneity in high-entropy alloys

Acta Mater. 224, 117527 (2022).

S. C. Dai, Z. C. Xie, and Y. J. Wang

Atomistic interpretation of extra temperature and strain-rate sensitivity of heterogeneous dislocation nucleation in a multi-principal-element alloy

Int. J. Plast. 149, 103155 (2022).

Y. L. Guan, W. D. Song, Y. J. Wang, S. S. Liu, and Y. J. Yua

Dynamic responses in shocked Cu-Zr nanoglasses with gradient microstructure

Int. J. Plast. 149, 103154 (2022).

– 2021 –

Y. J. Wang

An overview of molecular dynamics simulations of plasticity in solids at experimentally relevant timescales

Chinese J. Comput. Mech. 38, 280 (2021).

Z. Y. Yang, D. Wei, A. Zaccone, and Y. J. Wang

Machine-learning integrated glassy defect from an intricate configurational-thermodynamic-dynamic space

Phys. Rev. B 104, 064108 (2021).

G. J. Lyu, J. C. Qiao, Y. Yao, Y. J. Wang, J. Morthomas, C. Fusco, and D. Rodney

Microstructural effects on the dynamical relaxation of glasses and glass composites: A molecular dynamics study

Acta Mater. 220, 117293 (2021).

Z. H. Peng, Z. Y. Yang, and Y. J. Wang

Machine learning atomic-scale stiffness in metallic glass

Extreme Mech. Lett. 48, 101446 (2021).

Y. J. Duan, J. C. Qiao, T. Wada, H. Kato, E. Pineda, D. Crespo, and Y. J. Wang

Stress relaxation in high-entropy Pd20Pt20Cu20Ni20P20 metallic glass: Experiments, modeling and theory

Mech. Mater. 160, 103959 (2021).

E. L. Yue, T. Yu, Y. J. Wang, and C. Y. Wang

Synergistic strengthening mechanisms of rhenium in nickel-based single crystal superalloys

Intermetallics 132, 107133 (2021).

X. S. Yang, S. Q. Yuan, H. Fu, and Y. J. Wang

Grain boundary-mediated plasticity accommodating the cracking process in nanograined gold: In situ observations and simulations

Scr. Mater. 194, 113693 (2021).

Y. J. Duan, J. C. Qiao, T. Wada, H. Kato, Y. J. Wang, E. Pineda, D. Crespo

Inelastic deformation of metallic glasses under dynamic cyclic loading

Scr. Mater. 194, 113675 (2021).

L. T. Zhang, Y. J. Duan, D. Crespo, E. Pineda, Y. J. Wang, J. M. Pelletier, and J. C. Qiao

Dynamic mechanical relaxation and thermal creep of high-entropy La30Ce30Ni10Al20Co10 bulk metallic glass

Sci. China-Phys. Mech. Astron. 64, 296111 (2021).

Z. C. Xie, Y. J. Wang, C. S. Lu, and L. H. Dai

Sluggish hydrogen diffusion and hydrogen decreasing stacking fault energy in a high-entropy alloy

Mater. Today Commun. 26, 101902 (2021).

– 2020 –

Y. B. Yang, Q. Yang, D. Wei, L. H. Dai, H. B. Yu, and Y. J. Wang

Unraveling strongly entropic effect on β-relaxation in metallic glass: Insights from enhanced atomistic samplings over experimentally relevant timescales

Phys. Rev. B 102, 174103 (2020).

Y. J. Wang, D. Wei, D. Han, J. Yang, M. Q. Jiang, and L. H. Dai

Does structure determine property in amorphous solids?

Chinese J. Theor. Appl. Mech. 52, 303 (2020).

F. H. Cao, Y. J. Wang, and L. H. Dai

Novel atomic-scale mechanism of incipient plasticity in a chemically complex CrCoNi medium-entropy alloy associated with inhomogeneity in local chemical environment

Acta Mater. 194, 283-294 (2020).

D. Han, D. Wei, P. H. Cao, Y. J. Wang, and L. H. Dai

Statistical complexity of potential energy landscape as a dynamic signature of the glass transition

Phys. Rev. B 101, 064205 (2020).

D. Han, D. Wei, J. Yang, H. L. Li, M. Q. Jiang, Y. J. Wang, L. H. Dai, and A. Zaccone

Atomistic structural mechanism for the glass transition: Entropic contribution

Phys. Rev. B 101, 014113 (2020).

L. W. Liang, Y. J. Wang, Y. Chen, H. Y. Wang, and L. H. Dai

Dislocation nucleation and evolution at the ferrite-cementite interface under cyclic loadings

Acta Mater. 186, 267-277 (2020).

X. Li, D. Wei, J. Y. Zhang, X. D. Liu, Z. Li, T. Y. Wang, Q.F. He, Y. J. Wang, J. Ma, W. H. Wang, Y. Yang

Ultrasonic plasticity of metallic glass near room temperature

Appl. Mater. Today 21, 100866 (2020).

X. F. Liu, Z. L. Tian, X. F. Zhang, H. H. Chen, T. W. Liu, Y. Chen, Y. J. Wang, and L. H. Dai

“Self-sharpening” tungsten high-entropy alloy

Acta Mater. 186, 257-266 (2020).

J. Yang, J. Duan, Y. J. Wang, and M. Q. Jiang

Complexity of plastic instability in amorphous solids: Insights from spatiotemporal evolution of vibrational modes

Eur. Phys. J. E 43, 56 (2020).

Z. R. Xu, D. S. Yang, J. C. Qiao, J. M. Pelletier, D. Crespo, E. Pineda and Y. J. Wang

Unified perspective on structural heterogeneity of a LaCe-based metallic glass from versatile dynamic stimuli

Intermetallics 125, 106922 (2020).

Y. H. Chen, Y. J. Wang, and J. C. Qiao

Stress relaxation of La30Ce30Al15Co25 metallic glass

Chinese J. Theor. Appl. Mech. 52, 740 (2020).

– 2019 –

J. Yang, Y. J. Wang, A. Zaccone, E. Ma, L. H. Dai, and M. Q. Jiang

Structural Parameter of Orientational Order to Predict the Boson Vibrational Anomaly in Glasses

Phys. Rev. Lett. 122, 015501 (2019).

J. Ma, C. Yang, X. D. Liu, B. S. Shang, Q. F. He, F. C. Li, T. Y. Wang, D. Wei, X. Liang, X. Y. Wu, Y. J. Wang, F. Gong, P. F. Guan, W. H. Wang, and Y. Yang

Fast surface dynamics enabled cold joining of metallic glasses

Sci. Adv. 5, eaax7256 (2019).

D. Wei, J. Yang, M. Q. Jiang, B. C. Wei, Y. J. Wang, and L. H. Dai

Revisiting the structure–property relationships of metallic glasses: Common spatial correlation revealed as a hidden rule

Phys. Rev. B 99, 014115 (2019). (Figure was featured as a PRB Kaleidoscope)

D. Wei, J. Yang, M. Q. Jiang, L. H. Dai, Y. J. Wang, J. Dyre, I. Douglass, and Peter Harrowell

Assessing the Utility of Structure in Amorphous Materials

J. Chem. Phys. 150, 114502 (2019).

Z. Y. Yang, Y. J. Wang, and L. H. Dai

Susceptibility of shear banding to chemical short-range order in metallic glasses

Scr. Mater. 162, 141 (2019).

Y. Liu, S. L. Cai, M. Y. Su, Y. J. Wang, and L. H. Dai

Hierarchical-microstructure based modeling for plastic deformation of partial recrystallized copper

Mech. Mater. 139, 103207 (2019).

L. W. Liang, L. Xiang, Y. J. Wang, Y. Chen, H. Y. Wang, and L. H. Dai

Ratchetting in cold-drawn pearlitic steel wires

Metall. Mater. Trans. A 50, 4561 (2019).

L. Xiang, L. W. Liang, Y. J. Wang, Y. Chen, H. Y. Wang, and L. H. Dai

One-step annealing optimizes strength-ductility tradeoff in pearlitic steel wires

Mater. Sci. Eng. A 757, 1-13 (2019).

G. Aral, M. M. Islam, Y. J. Wang, S. Ogata, and A. C. T. van Duin

Atomistic insights on the influence of pre-oxide shell layer and size on the compressive mechanical properties of nickel nanowires

J. Appl. Phys. 125, 165102 (2019).

G.-J. J. Gao, Y. J. Wang, and S. Ogata

Incorporating a soft ordered phase into an amorphous configuration enhances its uniform plastic deformation under shear

AIP Adv. 9, 015329 (2019).

Y. Liu, S. L. Cai, F. G. Xu, Y. J. Wang, and L. D. Dai

Enhancing strength without compromising ductility in copper by combining extrusion machining and heat treatment

J. Mater. Process. Technol. 267, 52 (2019).

– 2018 –

Y. J. Wang, J. P. Du, S. Shinzato, L. H. Dai, and S. Ogata

A free energy landscape perspective on the nature of collective diffusion in amorphous solids

Acta Mater. 157, 165 (2018).

G. Aral, M. M. Islam, Y. J. Wang, S. Ogata, and A. C. T. van Duin

Oxyhydroxide of metallic nanowires in a molecular H2O and H2O2 environment and their effects on mechanical properties

Phys. Chem. Chem. Phys. 20, 17289 (2018).

– 2017 –

B. Y. Cui, J. Yang, J. C. Qiao, M. Q. Jiang, L. H. Dai, Y. J. Wang, and A. Zaccone

Atomic theory of viscoelastic response and memory effects in metallic glass

Phys. Rev. B 96, 094203 (2017).

Z. L. Tian, Y. J. Wang, Y. Chen, and L. H. Dai

Strain gradient drives shear banding in metallic glass

Phys. Rev. B 96, 094103 (2017).

M. Q. Jiang, M. Peterlechner, Y. J. Wang, W. H. Wang, F. Jiang, L. H. Dai, and G. Wilde

Universal structural softening in metallic glasses indicated by boson heat capacity peak

Appl. Phys. Lett. 111, 261901 (2017).

– 2016 –

J. C. Qiao, Y. J. Wang, L. Z. Zhao, L. H. Dai, D. Crespo, J. M. Pelletier, L. M. Keer, and Y. Yao

Transition from stress-driven to thermally activated stress relaxation in metallic glasses

Phys. Rev. B 94, 104203 (2016).

J. P. Du, Y. J. Wang, Y. C. Lo, L. Wan, and S. Ogata

Mechanism transition and strong temperature dependence of dislocation nucleation from grain boundaries: An accelerated molecular dynamics study

Phys. Rev. B 94, 104110 (2016).

X. S. Yang, Y. J. Wang, H. R. Zhai, G. Y. Wang, Y. J. Su, L. H. Dai, S. Ogata, and T. Y. Zhang

Time-, stress-, and temperature-dependent deformation in nanostructured copper: Creep tests and simulations

J. Mech. Phys. Solids 94, 191-206 (2016).

X. S. Yang, Y. J. Wang, G. Y. Wang, H. R. Zhai, L. H. Dai, and T. Y. Zhang

Time, stress and temperature-dependent deformation in nanostructured copper: stress relaxation tests and simulations

Acta Mater. 108, 252-263 (2016).

Y. J. Wang, K. Tsuchiya, and L. H. Dai

Size-dependent plastic deformation and failure mechanisms of nanotwinned Ni3Al: insights from an atomistic cracking model

Mater. Sci. Eng. A 649, 449 (2016).

Y. J. Wang, M. Q. Jiang, Z. L. Tian, and L. H. Dai

Direct atomic-scale evidence for shear–dilatation correlation in metallic glasses

Scr. Mater. 112, 37 (2016).

G. Aral, Y. J. Wang, S. Ogata, and Adri C. T. van Duin

Effects of oxidation on tensile deformation of iron nanowires: Insights from reactive molecular dynamics simulations

J. Appl. Phys. 120, 135104 (2016).

M. Zhang, Y. J. Wang, and L. H. Dai

Correlation between strain rate sensitivity and α relaxation of metallic glasses

AIP Adv. 6, 075022 (2016).

N. Miyazaki, M. Wakeda, Y. J. Wang, and S. Ogata

Prediction of pressure-promoted thermal rejuvenation in metallic glasses

npj Comput. Mater. 2, 16013 (2016).

X. Huang, Z. Ling, Y. J. Wang, and L. H. Dai

Intrinsic structural defects on medium range in metallic glasses

Intermetallics 75, 36-41 (2016).

M. Zhang, Y. J. Wang, and L. H. Dai

Understanding the serrated flow and Johari-Goldstein relaxation of metallic glasses

J. Non-Crystalline Solids 444, 23 (2016).

– 2015 –

Y. J. Wang, S. Ogata, and L. H. Dai

Universal enthalpy-entropy compensation rule in the deformation of metallic glasses

Phys. Rev. B 92,174118 (2015).

J. C. Qiao, Y. J. Wang, J. M. Pelletier, Leon M. Keer, Morris E. Fine, and Y. Yao

Characteristics of stress relaxation kinetics of La60Ni15Al25 bulk metallic glass

Acta Mater. 98, 43 (2015).

M. Q. Jiang, M. Naderi, Y. J. Wang, M. Peterlechner, X. F. Liu, F. Zeng, F. Jiang, L. H. Dai, and G. Wilde

Thermal expansion accompanying the glass-liquid transition and crystallization

AIP Adv. 5, 127133 (2015).

M. Zhang, Y. J. Wang, and L. H. Dai

Bridging shear transformation zone to the atomic structure of amorphous solids

J. Non-Crystalline Solids 410, 100 (2015).

– 2013 –

Y. J. Wang, G. J. Gao, and S. Ogata

Atomistic understanding of diffusion kinetics in nanocrystals from molecular dynamics simulations

Phys. Rev. B 88, 115413 (2013).

Y. J. Wang, A. Ishii, and S. Ogata

Entropic effect on creep in nanocrystalline metals

Acta Mater. 61, 3866 (2013).

Y. J. Wang, G. J. J. Gao, and S. Ogata

Size-dependent transition of deformation mechanism, and nonlinear elasticity in Ni3Al nanowires

Appl. Phys. Lett. 102, 041902 (2013).

S. Yamamoto, Y. J. Wang, A. Ishii, and S. Ogata

Atomistic design of high strength crystalline-amorphous nanocomposites

Mater. Trans. 54, 1592 (2013).

G. J. Gao, Y. J. Wang, and S. Ogata

Studying the elastic properties of nanocrystalline copper using a model of randomly packed uniform grains

Comput. Mater. Sci. 79, 56 (2013).

– 2012 –

Y. J. Wang, A. Ishii, and S. Ogata

Grain size dependence of creep in nanocrystalline copper by molecular dynamics

Mater. Trans. 53, 156-160 (2012).

– 2011 –

Y. J. Wang, A. Ishii, and S. Ogata

Transition of creep mechanism in nanocrystalline metals

Phys. Rev. B 84, 224102 (2011). (Figure was featured as a PRB Kaleidoscope)

Y. J. Wang, C. Y. Wang, and S. Y. Wang

CO adsorption on small Aun (n = 1-7) clusters supported on a reduced rutile TiO2(110) surface: a first-principles study

Chin. Phys. B 20, 036801 (2011).

– 2009 –

Y. J. Wang and C. Y. Wang

A comparison of the ideal strength between L12 Co3(Al,W) and Ni3Al under tension and shear from first-principles calculations

Appl. Phys. Lett. 94, 261909 (2009).

Y. J. Wang and C. Y. Wang

Influence of the alloying element Re on the ideal tensile and shear strength of γ'-Ni3Al

Scr. Mater. 61, 179-200 (2009).

Y. J. Wang and C. Y. Wang

Influence of the alloying elements on the elastic properties of the ternary and quaternary Nickel-base superalloys

Philos. Mag. 89, 2935-2947 (2009).

Y. J. Wang and C. Y. Wang

First-principles calculations for the elastic properties of Ni-base model superalloys: Ni/Ni3Al multilayers

Chin. Phys. B 18, 4339-4348 (2009).

Y. J. Wang and C. Y. Wang

Effect of alloying elements on the elastic properties of γ-Ni and γ'-Ni3Al from first-principles calculations

MRS Proceedings 1224, 1224-FF05-31 (2009).

Y. J. Wang and C. Y. Wang

Mechanical properties and electronic structure of superhard diamondlike BC5: a first-principles study

J. Appl. Phys. 106, 043513 (2009).

J. Wang and Y. J. Wang

Mechanical and electronic properties of 5d transition metal diborides MB2 (M = Re, W, Os, Ru)

J. Appl. Phys. 105, 083539 (2009).

– 2008 –

Y. J. Wang and C. Y. Wang

A first-principles survey of the partitioning behaviors of alloying elements on γ/γ' interface

J. Appl. Phys. 104, 013109 (2008).

Y. J. Wang and C. Y. Wang

The alloying mechanisms of Re, Ru in the quaternary Ni-based superalloys γ/γ' interface: a first principles calculation

Mater. Sci. Eng. A 490, 242-249 (2008).

科研项目

––主持项目––

- 2025-2028 国家自然科学基金面上项目,融合物理与数据驱动的无序物质智能本构模型

- 2022–2024 中国科学院青年创新促进会优秀会员人才专项经费

- 2021–2024 国家自然科学基金面上项目,新型无序固体塑性变形微观机制的熵效应

- 2017–2020 国家自然科学基金面上项目,金属玻璃应力松弛与蠕变多级动力学跨时间尺度计算机模拟

- 2017–2020 国家重点研发计划子课题,高通量并发式材料计算算法和软件

- 2017–2020 中国科学院青年创新促进会会员人才专项经费

- 2015–2017 国家自然科学基金青年科学基金,非晶/纳米晶复合材料原子尺度塑性机制

––参与项目––

- 2024–2027 国家重点研发计划,极小尺寸结构的建模和计算模拟研究

- 2023–2028 中国科学院B类先导专项, 极限晶粒金属的力学性能和使役性能以及电热输运性能研究

- 2017–2020 国家重点研发计划,多场耦合条件下金属结构材料损伤演化行为的跨尺度关联评价

- 2017–2020 国家自然基金重大项目,无序合金塑性流动与强韧化机理

- 2016–2020 中国科学院B类先导专项, 超常环境下系统力学问题研究与验证

国内外合作

具有广泛的国内外合作基础,与清华大学王崇愚院士、上海大学张统一院士、中科院物理所汪卫华院士、西北工大乔吉超教授、华中科技大学于海滨教授、香港城市大学杨勇教授、香港理工大学杨许生教授、中科院长春应化所徐文生研究员、深圳大学马将教授;大阪大学Shigenobu Ogata教授、米兰大学Alessio Zaccone教授、罗斯基洛大学Jeppe Dyre教授、美国国家标准与技术研究院Jack Douglas教授、悉尼大学Peter Harrowell教授、上海交大Matteo Baggioli教授等学者建立了密切合作关系。

社会兼职

编委:《计算力学学报》编委、《Materials Research Letters》青年编委、《Journal of Applied Physics》客座编辑。

会员: Materials Research Society (MRS), The Minerals, Metals & Materials Society (TMS), American Physical Society (APS), The Chinese Society of Theoretical and Applied Mechanics (CSTAM)

期刊审稿人: Nat. Phys., Phys. Rev. Lett., Phys. Rev. B/E/Materials, Nature Commun., PNAS, Acta/Scr. Mater., Adv. Mater., J. Phys. Chem. Lett., Mater. Toady Phys., J. Phys. Chem., Appl. Phys. Lett., APL Materials, J. Appl. Phys, Mater. Sci. Eng. A, MMTA, Sci. China, J Mater. Sci. Technol., etc.

教授课程

《现代计算力学导论》