Prof. Dr. Yun-Jiang WANG

State Key Laboratory of Nonlinear Mechanics

Institute of Mechanics, Chinese Academy of Science, Beijing, China

School of Engineering Science, University of Chinese Academy of Sciences, Beijing, China

Office Tel. +86 10 8254 3408

E-mail: yjwang@imech.ac.cn

--Short Bio--

Yun-Jiang Wang is currently a full professor at Institute of Mechanics, Chinese Academy of Sciences (CAS), Beijing, China. Before joining CAS in 2014, he was postdoc at Osaka University and assistant professor at Kyoto University from 2010-2013, after receiving his Ph.D. in Condensed Matter Physics from Tsinghua University in 2010. He is interested in multi-scale modelings and simulations of physics and mechanics of versatile novel solids, with particular interest in physical understanding of deformation in disordered solids (model/metallic glass, high-entropy alloy), nanocrystals, and high-temperautre materials, etc.

Research Interests

- Multiscale simulations & modellings of the mechanics and physics of novel solids, e.g. metallic glass, high-entropy alloys, and superalloys.

- Electronic- and atomic-level understanding of the various material processes, e.g., creep, stress relaxation, dislocation nucleation and motion, vibration and phonon, diffusion, internal friction, as well as the glass transition phenomenon.

- Overcoming time-scale limitation in atomistic simulations, including accelerated molecular dynamics, nudged elastic band method, machine learning, kinetic Monte Carlo and kART, etc.

Research gallery

Current Memebers of GDP -- Group of Deformation Physics

(left to right): Haozhi Xiong, Shicheng Dai, Kun Zhao, Zengyu Yang, Jiale Tao, Yunjiang Wang, Linli Cao, Xiaoshi Wang

Education

- 9/2005 -- 7/2010, Ph.D. in Physics, Tsinghua University, China.

9/2001 -- 7/2005, B.S. in Physics, Hebei Normal University, China

Professional Experience

11/2018 - Present Professor, Institute of Mechanics, CAS

01/2014 - 10/2018 Associate Professor, Institute of Mechanics, CAS

01/2013 - 12/2013 Program-specific Assistant Professor, Kyoto University

10/2010 - 12/2012 JSPS Postdoctoral Fellow, Osaka University (hosted by Prof. Shigenobu Ogata)

Honors & Distinctions

- 2023 Acta Materialia, Scripta Materialia Outstanding Reviewer Award

- 2023 IOP (Model. Simul. Mater. Sci. Eng.) Outstanding Reviewer Award

- 2021 Excellent Membership of the Youth Innovation Promotion Association, Chinese Academy of Sciences

- 2017 Membership of the Youth Innovation Promotion Association, Chinese Academy of Sciences

- 2010 JSPS Postdoctoral Fellowship, Japan

Publications

Linked to Google Scholar; Researchgate; WoS; Orcid

Y. J. Duan, M. Nabahat, Y. Tong, L. Ortiz-Membrado, E. Jiménez-Piqué, K. Zhao, Y. J. Wang, Y. Yang, T. Wada, H. Kato, J. M. Pelletier, J. C. Qiao, and E. Pineda

Connection between Mechanical Relaxation and Equilibration Kinetics in a High-Entropy Metallic Glass

Phys. Rev. Lett. 132, 056101 (2024).

S. C. Dai, Y. Yang, and Y. J. Wang

Role of chemical disorder in slowing down diffusion in complex concentrated alloys

Phys. Rev. Mater. 8, 033607 (2024).

L. L. Cao and Y. J. Wang

Dynamics–Entropy Relationship in Metallic Glasses

J. Phys. Chem. Lett. 15, 811 (2024).

Q. Hao, G. J. Lyu, E. Pineda, J. M. Pelletier, Y. J. Wang, Y. Yang, J. C. Qiao

Deciphering non-elastic deformation in amorphous alloy: Simultaneous aging-induced ordering and rejuvenation-induced disordering

Int. J. Plast. 175, 103926 (2024).

L. T. Zhang, Y. J. Wang, M. Nabahat, E. Pineda, Y. Yang, J. M. Pelletier, D. Crespo, J. C. Qiao

Creep Deformation in Metallic Glasses: A Global Approach with Strain as an Indicator within Transition State Theory

Int. J. Plast. 174, 103923 (2024).

F. Zhu, G.H. Xing, Y. J. Wang, E. Pineda, and J.C. Qiao

Quantifying contribution of hierarchically correlated shear microdomains underlying creep in metallic glass

Int. J. Plast. 174, 103900 (2024).

X. Gao, S. C. Dai, Y. Teng, Q. Wang, Z. B. Zhang, Z. Y. Yang, M. Park, H. Wang, Z. Jia, Y. J. Wang, and Y. Yang

Ultra-Efficient and Cost-Effective Platinum Nanomembrane Electrocatalyst for Sustainable Hydrogen Production

Nano-Micro Lett. 16, 108 (2024).

H. L. Zhuang, Z. Z. Yu, L. Li, Y. J. Wang, and L, K. Béland

Multi-principal element materials: Structure, property, and processing

J. Appl. Phys. 135, 010401 (2024).

P. Y. Cao, J. Wang, P. Jiang, Y. J. Wang, F. P.Yuan, and X. L. Wu

Prediction of chemical short-range order in high-/medium-entropy alloys

J. Mater. Sci. Technol. 169, 115 (2024).

S. Y. Liang, L. T. Zhang, B. Wang, Y. J. Wang, E. Pineda, and J. C. Qiao,

Structural rejuvenation and relaxation of a metallic glass under the periodically thermal-mechanical loading

Intermetallics 164, 108115 (2024).

– 2023 –

X. S. Wang and Y. J. Wang

Phonon instability of a multi-principal element alloy

Phys. Rev. B 107, 184116 (2023).

P. A. Santos-Florez, S. C. Dai, Y. Yao, H. Yanxon, L. Li, Y. J. Wang, Qiang Zhu, and X. X. Yu

Short-range order and its impacts on the BCC MoNbTaW multi-principal element alloy by the machine-learning potential

Acta Mater. 255, 119041 (2023).

J. L. Tao, Z. Y. Yang, and Y. J. Wang

Structural rationale for boson peak in metallic glass informed by an interpretable neural network model

Phys. Rev. Res. 5, 023113 (2023).

K. Zhao, Y. J. Wang, and P. H. Cao

Fracture universality in amorphous nanowires

J. Mech. Phys. Solids 173, 105210 (2023).

X. S. Wang and Y. J. Wang

Disorder-order transition in multiprincipal element alloy: A free energy perspective

Phys. Rev. Mater. 7, 033606 (2023).

Z. Y. Zhou, Y. Sun, L. Gao, Y. J. Wang, H. B.Yu

Fundamental links between shear transformation, β relaxation, and string-like motion in metallic glasses

Acta Mater. 246, 118701 (2023).

L. Qian, W. Q. Yang, J. S. Luo, Y. J. Wang, K. C. Chan, and X. S. Yang

Amorphous Thickness-Dependent Strengthening–Softening Transition in Crystalline–Amorphous Nanocomposites

Nano Lett. 23, 11288 (2023).

Y. J. Bai, Y. D. Li, Y. J. Wang, K. Zhang, Q. Y. Jiang, Z. S. Liu, Z. Hu, and B. C. Wei

Wavy interface enables extra strengthening in an additively manufactured high-entropy alloy with Mortise-Tenon architecture

Int. J. Plast. 170, 103777 (2023).

Q. Hao, E. Pineda, Y. J. Wang, Y. Yang and J. C. Qiao

Reversible anelastic deformation mediated by β relaxation and resulting two-step deformation in a La60Ni15Al25 metallic glass

Phys. Rev. B 108, 024101 (2023).

F. Zhu, G.H. Xing, G.J. Lyu, L.T. Zhang, Y. J. Wang, Y. Yang, J.M. Pelletier, J.C. Qiao

Physics-motivated fractional viscoelasticity model for dynamic relaxation in amorphous solids

Int. J. Plast. 164, 103588 (2023).

L. T. Zhang, Y. J. Wang, Y. Yang, J. C. Qiao

Training β relaxation to rejuvenate metallic glasses

J. Mater. Sci. Technol. 158, 53 (2023).

Y. J. Bai, G. J. Lyu, Y. J. Wang, T. Y. Chen, K. Zhang, and B. C. Wei

Laser shock peening strengthens additively manufactured high-entropy alloy through novel surface grain rotation

Mater. Sci. Eng. A 871, 144886 (2023).

L. Y. Li, G. J. Lyu, H. Z. Li, C. T. Fan, W. X. Wen, H. J. Lin, B. Huang, S. Sohrabi, S. Ren, X. Liang, Y. J. Wang, J. Ma, and W. H. Wang

Ultra-fast amorphization of crystalline alloys by ultrasonic vibrations

J. Mater. Sci. Technol. 142, 76 (2023).

L. W. Liang, S. C. Dai, Y. Chen, H. Y. Wang, Y. J. Wang and L. H. Dai

Emergent failure transition of pearlitic steel at extremely high strain rates

Comput. Mater. Sci. 219, 112005 (2023).

J. Duan, Y. J. Wang, L. H. Dai, and M. Q. Jiang

Elastic interactions of plastic events in strained amorphous solids before yield

Phys. Rev. Materials 7, 013601 (2023).

S. Shuang, G. J. Lyu, D. Chung, X. Z. Wang, X. Gao, H. H. Mao, W. P. Li, Q. F. He, B. S. Guo, X. Y. Zhong, Y. J. Wang, and Y. Yang

Unusually high corrosion resistance in MoxCrNiCo medium entropy alloy enhanced by acidity in aqueous solution

J. Mater. Sci. Technol. 139, 59 (2023).

L. T. Zhang, Y. J. Duan, Y. J. Wang, Y. Yang, and J. C. Qiao

Tailoring mechanical properties of bulk metallic glasses via modulating cooling from supercooled liquid

Sci. China Technol. Sci. 66, 173 (2023).

– 2022 –

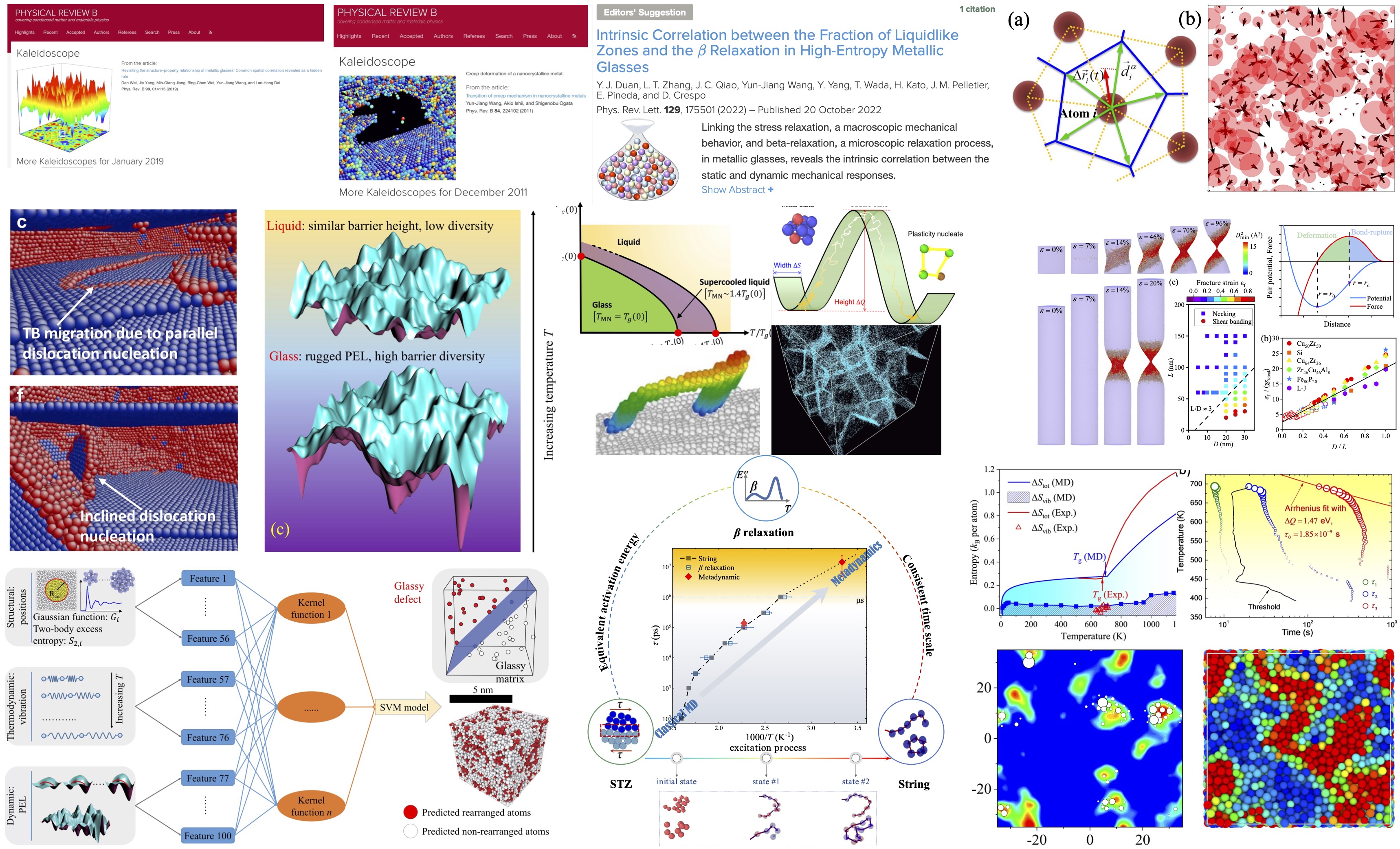

Y. J. Duan, L. T. Zhang, J. C. Qiao, Y. J. Wang, Y. Yang, T. Wada, H. Kato, J. M. Pelletier, E. Pineda, and D. Crespo

Intrinsic Correlation between the Fraction of Liquidlike Zones and the β Relaxation in High-Entropy Metallic Glasses

Phys. Rev. Lett. 129, 175501 (2022). (Editors' Suggestion)

Y. J. Bai, K. Zhang, T. Y. Chen, Z. S. Liu, Y. J. Wang, B. C. Wei

Alterable tension-compression asymmetry in work hardening of an additively manufactured dual-phase high-entropy alloy

Int. J. Plast. 158, 103432 (2022).

L. T. Zhang, Y. J. Wang, Y. Yang, and J. C. Qiao

Aging and rejuvenation during high-temperature deformation in a metallic glass

Sci. China-Phys. Mech. Astron. 65, 106111 (2022).

Y. L. Guan, Y. J. Wang, and W. D. Song

Modulating mechanical performances of metallic amorphous materials through phase gradient

Int. J. Mech. Sci. 234, 107680 (2022).

L. T. Zhang, Y. J. Wang, E. Pineda, Y. Yang, and J. C. Qiao

Achieving structural rejuvenation in metallic glass by modulating β relaxation intensity via easy-to-operate mechanical cycling

Int. J. Plast. 157, 103402 (2022).

Z. Y. Yang, Y. J. Wang, and L. H. Dai

Hidden spatiotemporal sequence in transition to shear band in amorphous solids

Phys. Rev. Research 4, 023220 (2022).

X. J. Wang, Y. Z. Lu, X. Lu, J. T. Huo, Y. J. Wang, W. H. Wang, L. H. Dai, and M. Q. Jiang

Elastic criterion for shear-banding instability in amorphous solids

Phys. Rev. E 105, 045003 (2022).

Z. Y. Yang and Y. J. Wang

Ergodic structural diversity predicts dynamics in amorphous materials

Front. Mater. (2022).

L. T. Zhang, Y. J. Wang, E. Pineda, H. Kato, Y. Yang, and J. C.Qiao

Sluggish dynamics of homogeneous flow in high-entropy metallic glasses

Scr. Mater. 214, 114673 (2022).

Q. Hao, G. J. Lyu, E. Pineda, J. M. Pelletier, Y. J. Wang, Y. Yang, and J. C. Qiao

A hierarchically correlated flow defect model for metallic glass: Universal understanding of stress relaxation and creep

Int. J. Plast. 154, 103288 (2022).

Z. Y. Yang and Y. J. Wang

Correlation between vibrational anomalies and emergent anharmonicity of the local potential energy landscape in metallic glasses

Phys. Rev. B 105, 014204 (2022).

Y. Z. Wang and Y. J. Wang

Disentangling diffusion heterogeneity in high-entropy alloys

Acta Mater. 224, 117527 (2022).

S. C. Dai, Z. C. Xie, and Y. J. Wang

Atomistic interpretation of extra temperature and strain-rate sensitivity of heterogeneous dislocation nucleation in a multi-principal-element alloy

Int. J. Plast. 149, 103155 (2022).

Y. L. Guan, W. D. Song, Y. J. Wang, S. S. Liu, and Y. J. Yua

Dynamic responses in shocked Cu-Zr nanoglasses with gradient microstructure

Int. J. Plast. 149, 103154 (2022).

– 2021 –

Y. J. Wang

An overview of molecular dynamics simulations of plasticity in solids at experimentally relevant timescales

Chinese J. Comput. Mech. 38, 280 (2021).

Z. Y. Yang, D. Wei, A. Zaccone, and Y. J. Wang

Machine-learning integrated glassy defect from an intricate configurational-thermodynamic-dynamic space

Phys. Rev. B 104, 064108 (2021).

G. J. Lyu, J. C. Qiao, Y. Yao, Y. J. Wang, J. Morthomas, C. Fusco, and D. Rodney

Microstructural effects on the dynamical relaxation of glasses and glass composites: A molecular dynamics study

Acta Mater. 220, 117293 (2021).

Z. H. Peng, Z. Y. Yang, and Y. J. Wang

Machine learning atomic-scale stiffness in metallic glass

Extreme Mech. Lett. 48, 101446 (2021).

Y. J. Duan, J. C. Qiao, T. Wada, H. Kato, E. Pineda, D. Crespo, and Y. J. Wang

Stress relaxation in high-entropy Pd20Pt20Cu20Ni20P20 metallic glass: Experiments, modeling and theory

Mech. Mater. 160, 103959 (2021).

E. L. Yue, T. Yu, Y. J. Wang, and C. Y. Wang

Synergistic strengthening mechanisms of rhenium in nickel-based single crystal superalloys

Intermetallics 132, 107133 (2021).

X. S. Yang, S. Q. Yuan, H. Fu, and Y. J. Wang

Grain boundary-mediated plasticity accommodating the cracking process in nanograined gold: In situ observations and simulations

Scr. Mater. 194, 113693 (2021).

Y. J. Duan, J. C. Qiao, T. Wada, H. Kato, Y. J. Wang, E. Pineda, D. Crespo

Inelastic deformation of metallic glasses under dynamic cyclic loading

Scr. Mater. 194, 113675 (2021).

L. T. Zhang, Y. J. Duan, D. Crespo, E. Pineda, Y. J. Wang, J. M. Pelletier, and J. C. Qiao

Dynamic mechanical relaxation and thermal creep of high-entropy La30Ce30Ni10Al20Co10 bulk metallic glass

Sci. China-Phys. Mech. Astron. 64, 296111 (2021).

Z. C. Xie, Y. J. Wang, C. S. Lu, and L. H. Dai

Sluggish hydrogen diffusion and hydrogen decreasing stacking fault energy in a high-entropy alloy

Mater. Today Commun. 26, 101902 (2021).

– 2020 –

Y. B. Yang, Q. Yang, D. Wei, L. H. Dai, H. B. Yu, and Y. J. Wang

Unraveling strongly entropic effect on β-relaxation in metallic glass: Insights from enhanced atomistic samplings over experimentally relevant timescales

Phys. Rev. B 102, 174103 (2020).

Y. J. Wang, D. Wei, D. Han, J. Yang, M. Q. Jiang, and L. H. Dai

Does structure determine property in amorphous solids?

Chinese J. Theor. Appl. Mech. 52, 303 (2020).

F. H. Cao, Y. J. Wang, and L. H. Dai

Novel atomic-scale mechanism of incipient plasticity in a chemically complex CrCoNi medium-entropy alloy associated with inhomogeneity in local chemical environment

Acta Mater. 194, 283-294 (2020).

D. Han, D. Wei, P. H. Cao, Y. J. Wang, and L. H. Dai

Statistical complexity of potential energy landscape as a dynamic signature of the glass transition

Phys. Rev. B 101, 064205 (2020).

D. Han, D. Wei, J. Yang, H. L. Li, M. Q. Jiang, Y. J. Wang, L. H. Dai, and A. Zaccone

Atomistic structural mechanism for the glass transition: Entropic contribution

Phys. Rev. B 101, 014113 (2020).

L. W. Liang, Y. J. Wang, Y. Chen, H. Y. Wang, and L. H. Dai

Dislocation nucleation and evolution at the ferrite-cementite interface under cyclic loadings

Acta Mater. 186, 267-277 (2020).

X. Li, D. Wei, J. Y. Zhang, X. D. Liu, Z. Li, T. Y. Wang, Q.F. He, Y. J. Wang, J. Ma, W. H. Wang, Y. Yang

Ultrasonic plasticity of metallic glass near room temperature

Appl. Mater. Today 21, 100866 (2020).

X. F. Liu, Z. L. Tian, X. F. Zhang, H. H. Chen, T. W. Liu, Y. Chen, Y. J. Wang, and L. H. Dai

“Self-sharpening” tungsten high-entropy alloy

Acta Mater. 186, 257-266 (2020).

J. Yang, J. Duan, Y. J. Wang, and M. Q. Jiang

Complexity of plastic instability in amorphous solids: Insights from spatiotemporal evolution of vibrational modes

Eur. Phys. J. E 43, 56 (2020).

Z. R. Xu, D. S. Yang, J. C. Qiao, J. M. Pelletier, D. Crespo, E. Pineda and Y. J. Wang

Unified perspective on structural heterogeneity of a LaCe-based metallic glass from versatile dynamic stimuli

Intermetallics 125, 106922 (2020).

Y. H. Chen, Y. J. Wang, and J. C. Qiao

Stress relaxation of La30Ce30Al15Co25 metallic glass

Chinese J. Theor. Appl. Mech. 52, 740 (2020).

– 2019 –

J. Yang, Y. J. Wang, A. Zaccone, E. Ma, L. H. Dai, and M. Q. Jiang

Structural Parameter of Orientational Order to Predict the Boson Vibrational Anomaly in Glasses

Phys. Rev. Lett. 122, 015501 (2019).

J. Ma, C. Yang, X. D. Liu, B. S. Shang, Q. F. He, F. C. Li, T. Y. Wang, D. Wei, X. Liang, X. Y. Wu, Y. J. Wang, F. Gong, P. F. Guan, W. H. Wang, and Y. Yang

Fast surface dynamics enabled cold joining of metallic glasses

Sci. Adv. 5, eaax7256 (2019).

D. Wei, J. Yang, M. Q. Jiang, B. C. Wei, Y. J. Wang, and L. H. Dai

Revisiting the structure–property relationships of metallic glasses: Common spatial correlation revealed as a hidden rule

Phys. Rev. B 99, 014115 (2019). (Figure was featured as a PRB Kaleidoscope)

D. Wei, J. Yang, M. Q. Jiang, L. H. Dai, Y. J. Wang, J. Dyre, I. Douglass, and Peter Harrowell

Assessing the Utility of Structure in Amorphous Materials

J. Chem. Phys. 150, 114502 (2019).

Z. Y. Yang, Y. J. Wang, and L. H. Dai

Susceptibility of shear banding to chemical short-range order in metallic glasses

Scr. Mater. 162, 141 (2019).

Y. Liu, S. L. Cai, M. Y. Su, Y. J. Wang, and L. H. Dai

Hierarchical-microstructure based modeling for plastic deformation of partial recrystallized copper

Mech. Mater. 139, 103207 (2019).

L. W. Liang, L. Xiang, Y. J. Wang, Y. Chen, H. Y. Wang, and L. H. Dai

Ratchetting in cold-drawn pearlitic steel wires

Metall. Mater. Trans. A 50, 4561 (2019).

L. Xiang, L. W. Liang, Y. J. Wang, Y. Chen, H. Y. Wang, and L. H. Dai

One-step annealing optimizes strength-ductility tradeoff in pearlitic steel wires

Mater. Sci. Eng. A 757, 1-13 (2019).

G. Aral, M. M. Islam, Y. J. Wang, S. Ogata, and A. C. T. van Duin

Atomistic insights on the influence of pre-oxide shell layer and size on the compressive mechanical properties of nickel nanowires

J. Appl. Phys. 125, 165102 (2019).

G.-J. J. Gao, Y. J. Wang, and S. Ogata

Incorporating a soft ordered phase into an amorphous configuration enhances its uniform plastic deformation under shear

AIP Adv. 9, 015329 (2019).

Y. Liu, S. L. Cai, F. G. Xu, Y. J. Wang, and L. D. Dai

Enhancing strength without compromising ductility in copper by combining extrusion machining and heat treatment

J. Mater. Process. Technol. 267, 52 (2019).

– 2018 –

Y. J. Wang, J. P. Du, S. Shinzato, L. H. Dai, and S. Ogata

A free energy landscape perspective on the nature of collective diffusion in amorphous solids

Acta Mater. 157, 165 (2018).

G. Aral, M. M. Islam, Y. J. Wang, S. Ogata, and A. C. T. van Duin

Oxyhydroxide of metallic nanowires in a molecular H2O and H2O2 environment and their effects on mechanical properties

Phys. Chem. Chem. Phys. 20, 17289 (2018).

– 2017 –

B. Y. Cui, J. Yang, J. C. Qiao, M. Q. Jiang, L. H. Dai, Y. J. Wang, and A. Zaccone

Atomic theory of viscoelastic response and memory effects in metallic glass

Phys. Rev. B 96, 094203 (2017).

Z. L. Tian, Y. J. Wang, Y. Chen, and L. H. Dai

Strain gradient drives shear banding in metallic glass

Phys. Rev. B 96, 094103 (2017).

M. Q. Jiang, M. Peterlechner, Y. J. Wang, W. H. Wang, F. Jiang, L. H. Dai, and G. Wilde

Universal structural softening in metallic glasses indicated by boson heat capacity peak

Appl. Phys. Lett. 111, 261901 (2017).

– 2016 –

J. C. Qiao, Y. J. Wang, L. Z. Zhao, L. H. Dai, D. Crespo, J. M. Pelletier, L. M. Keer, and Y. Yao

Transition from stress-driven to thermally activated stress relaxation in metallic glasses

Phys. Rev. B 94, 104203 (2016).

J. P. Du, Y. J. Wang, Y. C. Lo, L. Wan, and S. Ogata

Mechanism transition and strong temperature dependence of dislocation nucleation from grain boundaries: An accelerated molecular dynamics study

Phys. Rev. B 94, 104110 (2016).

X. S. Yang, Y. J. Wang, H. R. Zhai, G. Y. Wang, Y. J. Su, L. H. Dai, S. Ogata, and T. Y. Zhang

Time-, stress-, and temperature-dependent deformation in nanostructured copper: Creep tests and simulations

J. Mech. Phys. Solids 94, 191-206 (2016).

X. S. Yang, Y. J. Wang, G. Y. Wang, H. R. Zhai, L. H. Dai, and T. Y. Zhang

Time, stress and temperature-dependent deformation in nanostructured copper: stress relaxation tests and simulations

Acta Mater. 108, 252-263 (2016).

Y. J. Wang, K. Tsuchiya, and L. H. Dai

Size-dependent plastic deformation and failure mechanisms of nanotwinned Ni3Al: insights from an atomistic cracking model

Mater. Sci. Eng. A 649, 449 (2016).

Y. J. Wang, M. Q. Jiang, Z. L. Tian, and L. H. Dai

Direct atomic-scale evidence for shear–dilatation correlation in metallic glasses

Scr. Mater. 112, 37 (2016).

G. Aral, Y. J. Wang, S. Ogata, and Adri C. T. van Duin

Effects of oxidation on tensile deformation of iron nanowires: Insights from reactive molecular dynamics simulations

J. Appl. Phys. 120, 135104 (2016).

M. Zhang, Y. J. Wang, and L. H. Dai

Correlation between strain rate sensitivity and α relaxation of metallic glasses

AIP Adv. 6, 075022 (2016).

N. Miyazaki, M. Wakeda, Y. J. Wang, and S. Ogata

Prediction of pressure-promoted thermal rejuvenation in metallic glasses

npj Comput. Mater. 2, 16013 (2016).

X. Huang, Z. Ling, Y. J. Wang, and L. H. Dai

Intrinsic structural defects on medium range in metallic glasses

Intermetallics 75, 36-41 (2016).

M. Zhang, Y. J. Wang, and L. H. Dai

Understanding the serrated flow and Johari-Goldstein relaxation of metallic glasses

J. Non-Crystalline Solids 444, 23 (2016).

– 2015 –

Y. J. Wang, S. Ogata, and L. H. Dai

Universal enthalpy-entropy compensation rule in the deformation of metallic glasses

Phys. Rev. B 92,174118 (2015).

J. C. Qiao, Y. J. Wang, J. M. Pelletier, Leon M. Keer, Morris E. Fine, and Y. Yao

Characteristics of stress relaxation kinetics of La60Ni15Al25 bulk metallic glass

Acta Mater. 98, 43 (2015).

M. Q. Jiang, M. Naderi, Y. J. Wang, M. Peterlechner, X. F. Liu, F. Zeng, F. Jiang, L. H. Dai, and G. Wilde

Thermal expansion accompanying the glass-liquid transition and crystallization

AIP Adv. 5, 127133 (2015).

M. Zhang, Y. J. Wang, and L. H. Dai

Bridging shear transformation zone to the atomic structure of amorphous solids

J. Non-Crystalline Solids 410, 100 (2015).

– 2013 –

Y. J. Wang, G. J. Gao, and S. Ogata

Atomistic understanding of diffusion kinetics in nanocrystals from molecular dynamics simulations

Phys. Rev. B 88, 115413 (2013).

Y. J. Wang, A. Ishii, and S. Ogata

Entropic effect on creep in nanocrystalline metals

Acta Mater. 61, 3866 (2013).

Y. J. Wang, G. J. J. Gao, and S. Ogata

Size-dependent transition of deformation mechanism, and nonlinear elasticity in Ni3Al nanowires

Appl. Phys. Lett. 102, 041902 (2013).

S. Yamamoto, Y. J. Wang, A. Ishii, and S. Ogata

Atomistic design of high strength crystalline-amorphous nanocomposites

Mater. Trans. 54, 1592 (2013).

G. J. Gao, Y. J. Wang, and S. Ogata

Studying the elastic properties of nanocrystalline copper using a model of randomly packed uniform grains

Comput. Mater. Sci. 79, 56 (2013).

– 2012 –

Y. J. Wang, A. Ishii, and S. Ogata

Grain size dependence of creep in nanocrystalline copper by molecular dynamics

Mater. Trans. 53, 156-160 (2012).

– 2011 –

Y. J. Wang, A. Ishii, and S. Ogata

Transition of creep mechanism in nanocrystalline metals

Phys. Rev. B 84, 224102 (2011). (Figure was featured as a PRB Kaleidoscope)

Y. J. Wang, C. Y. Wang, and S. Y. Wang

CO adsorption on small Aun (n = 1-7) clusters supported on a reduced rutile TiO2(110) surface: a first-principles study

Chin. Phys. B 20, 036801 (2011).

– 2009 –

Y. J. Wang and C. Y. Wang

A comparison of the ideal strength between L12 Co3(Al,W) and Ni3Al under tension and shear from first-principles calculations

Appl. Phys. Lett. 94, 261909 (2009).

Y. J. Wang and C. Y. Wang

Influence of the alloying element Re on the ideal tensile and shear strength of γ'-Ni3Al

Scr. Mater. 61, 179-200 (2009).

Y. J. Wang and C. Y. Wang

Influence of the alloying elements on the elastic properties of the ternary and quaternary Nickel-base superalloys

Philos. Mag. 89, 2935-2947 (2009).

Y. J. Wang and C. Y. Wang

First-principles calculations for the elastic properties of Ni-base model superalloys: Ni/Ni3Al multilayers

Chin. Phys. B 18, 4339-4348 (2009).

Y. J. Wang and C. Y. Wang

Effect of alloying elements on the elastic properties of γ-Ni and γ'-Ni3Al from first-principles calculations

MRS Proceedings 1224, 1224-FF05-31 (2009).

Y. J. Wang and C. Y. Wang

Mechanical properties and electronic structure of superhard diamondlike BC5: a first-principles study

J. Appl. Phys. 106, 043513 (2009).

J. Wang and Y. J. Wang

Mechanical and electronic properties of 5d transition metal diborides MB2 (M = Re, W, Os, Ru)

J. Appl. Phys. 105, 083539 (2009).

– 2008 –

Y. J. Wang and C. Y. Wang

A first-principles survey of the partitioning behaviors of alloying elements on γ/γ' interface

J. Appl. Phys. 104, 013109 (2008).

Y. J. Wang and C. Y. Wang

The alloying mechanisms of Re, Ru in the quaternary Ni-based superalloys γ/γ' interface: a first principles calculation

Mater. Sci. Eng. A 490, 242-249 (2008).

Research Funds

- Financial support for the Excellent Membership of the Youth Innovation Promotion Association, 2 000 000 CNY, CAS, 2022-2024

- "Entropic effect on microscopic mechanisms of plastic deformation in novel disordered solids", 630 000 CNY, NSFC, 2021-2024

- "High throughput concurrent algorithm and software for materials simulation", 900 000 CNY, National Key Research & Development Program of China, 2017-2021

- "Multi-time-scale computer simulations of the hierarchical dynamics in stress relaxation and creep of metallic glasses", 680 000 CNY, NSFC, 2017-2020

- Financial support for the Membership of the Youth Innovation Promotion Association, 800 000 CNY, CAS, 2017-2020

- "Atomic-scale ductile mechanism of amorphous-crystalline nanocomposite", 280 000 CNY, NSFC, 2015-2017

- "Computational design of next next generation nano-structured Nickel-based alloy", Grant-in-Aid for Scientific Research, 2,200,000 JPY, JSPS, 2010-2012

Academic Activities

Editorial board of "Chinese Journal of Computational Mechanics", Associate Editorial Board of "Materials Research Letters", Guest editor of "Journal of Applied Physics", Review Editor of "Frontiers in Materials"

Memberships: Materials Research Society (MRS), The Minerals, Metals & Materials Society (TMS), American Physical Society (APS), The Chinese Society of Theoretical and Applied Mechanics (CSTAM)

Reviewer for journals: Nat. Phys., Phys. Rev. Lett., Phys. Rev. B/E/Materials, Nature Commun., PNAS, Acta/Scr. Mater., Adv. Mater., J. Phys. Chem. Lett., Mater. Today Phys., J. Phys. Chem., Appl. Phys. Lett., APL Materials, J. Appl. Phys, Mater. Sci. Eng. A, MMTA, Sci. China, etc.

Teaching

Introduction to modern computational mechanics